User Friendly Interface

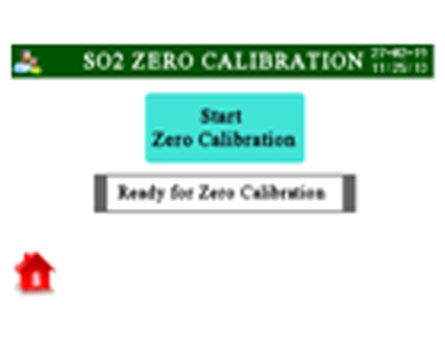

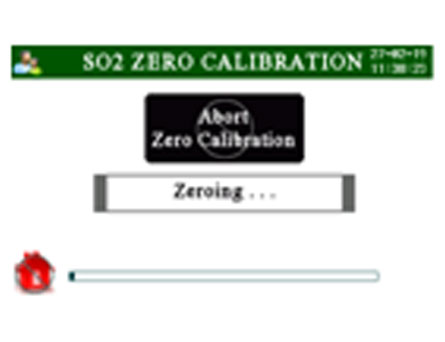

The colour touch screen and intuitive interface available makes very easy to test or configure the Analyzer. The interface allows offers features like measuring, zeroing, calibration, service and more. A USB port is provided to download the last 24hours recorded measurements as well as a diagnostic file containing the configuration and useful information for remote troubleshooting. The software of the controller can also be upgraded by connecting a USB key. An RS232/485 port supports MODBUS protocol to transmit each measuring channel value to a Data Acquisation System and can be connected a SCADA system. Additional parameters like status code, error code, calibration values, are available as Standard protocols in Diagnostics.

Previous Product

Previous Product